ENGINEERING

Total solution

In addition to producing precision castings, machining of cast pieces, assembly of sub-components, surface treatments, laser Marking are considered as a Total Solution to satisfy a particular specification of our customers.

These activities are performed at own factories and External specific process specialists. This will be the great advantage for our customer to purchase completely finished product.

This put an end to problems with quality, product liabilities & Communication. Because your contact person will be the one. This make you burden free and you are assured of high-quality Cast Parts.

Heat treatments

Heat treatment of castings is primarily used to alter the physical properties of the cast alloy. Many of the mechanical properties of steel alloys are determined by their microstructure. Heat treatment Is an efficient way of manipulating the crystalline structure of the alloy to modify its mechanical behavior in a predictable way. Controlled heating and cooling can have an impact on properties such as hardness, strength, toughness, ductility and elasticity although changing the properties of one to achieve a desired outcome will often change another – not always in a desirable direction.

The four basic types of heat treatment processes used today are –

- Annealing

- Normalizing

- Hardening

- Tempering

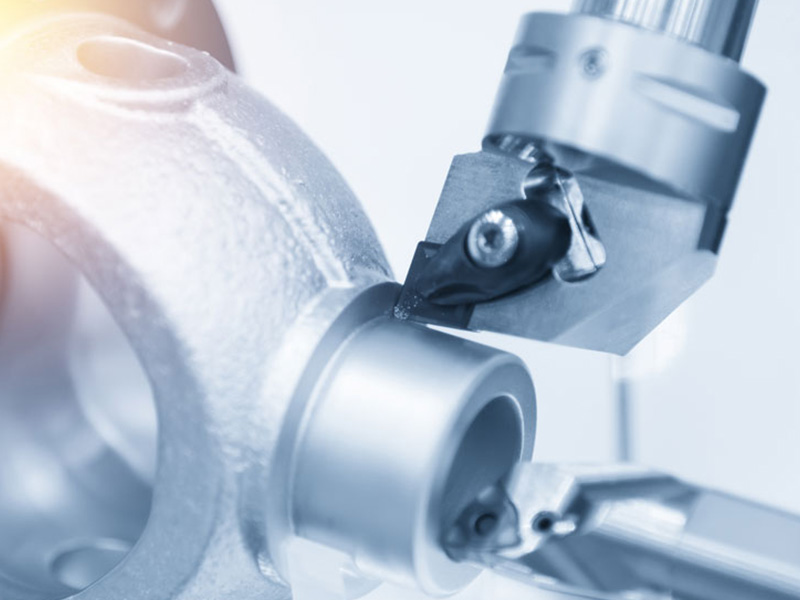

Machining of castings

The machining of cast pieces is done by our network of specialized machined shop. Here, we performed, turning, milling, planing and drilling, slotting and tapping either simple or complex.

Surface treatments

Unfortunately, We do not have own facilities for performing surface treatments in-house. Although knowledge in this area is available, it turns out to be cheaper to use external suppliers. This allows us to offer your surface treatment with competitive rates and your products are delivered ready to be built in.

Assembly

In addition, if your product must be assembled from multiple subcomponents, we can remove this burden from you. for example, joining parts with bolts, welding, or male-female assemblies, etc. This eliminates issues concerning quality problems and product liabilities.

PMI (Positive material identification)

Positive Material Identification is the analysis of a metallic alloy to establish composition by reading the quantities by percentage of its constituent elements. It’s on spot, non-destructive test which is be done to verifies the compliance of the chemical composition of the materials used on final cast piece, however it is not the standard practice to determine the material complains but mostly it is used to check for weld spots, joints to ensure elements for corrosion resistance capability.

Today there are analyzers offering different types of technologies. At COSMOS we are using XRF technology which is more than enough to determine the scope.

However, this facility is outsourcing with our approved service provider with extra cost whenever required by the customer.