ENGINEERING

Product evaluation

When COSMOS starts the series production of a product, the pre-series products are first evaluated. These products are inspected internally for dimensioning and material properties. If so desired, destructive, non-destructive or microstructural analysis also be performed.

In addition, the components are delivered to the customer for evaluation. The customer has to test the product for functionality, dimensions, strength, appearance and various other important parameters. Based on the results, it is determined whether the product is ready to be produced in series or if additional technical adaptations need to be implemented.

High product quality is safeguarded by means of evaluation phase, to implement stable production process and delivery reliability. All of this is combined with a favorable price level.

Dimension Measurement

Once the first pieces have been cast, the product is inspected for its dimensions because ‘Measuring is knowing’ is an important aphorism, In this manner, customers and OUR Engineers have a good picture of the cast piece. All of the measurement data are summarized in a measurement report and recorded precisely.

If measurement report found Any deviations in the dimensions are discussed with the customer. If it involves a functional dimension, then we coordinate jointly about the improvement of this dimension. This can be achieved through small changes in the Tool. If it involves non-functional dimensions, the decision may be made to use the product as it is. Dimensioning is an extremely important aspect, but functionality and deployability also play an important role.

Material Analysis

We use a spectrometer for the precise analysis of the chemical composition of steel for each and every heat melted. A spectrometer is an instrument for studying the spectrum of light and determining the composition of materials by means of that spectrum.

The results of the spectrometer analysis are Stored into system and processed into a report. This report is delivered by default along with your delivery of product as a MTC( Material Test Certificate). This single summary makes it clear which alloy elements comprise a given production batch and whether this complies with the specification.

At Cosmos, the spectrometer is linked to a computer. The reports are stored on the network so that the information is always available. Proper archiving of this information ensures the traceability of each cast piece.

Destructive analysis (DA)

To determine how strong, flexible or deformable a material is, or to determine its lifespan, products can be tested on the failure bench. Destructive analysis can be performed if the mechanical properties need to be known for the application of the casting.

Tensile Test

We have our Own equipment for performing tensile tests. In a tensile test, a standardized test bar is placed between two clamps in a tensile testing bench. Using a hydraulic or spindle drive, the bar is placed under stress and exposed to a maximum load until failure occurs.

The results of a tensile test or illustrated in a graph, the so-called stress-strain curve.

Impact Test

Impact tests are used in studying the toughness of material. A material’s toughness is a factor of its ability to absorb energy during plastic deformation. Brittle materials have low toughness as a result of the small amount of plastic deformation that they can endure. The impact value of a material can also changes with temperature. Generally, at lower temperatures, the impact energy of a material is decreased. We do Charpy V-Notch test in house with low temperature settings.

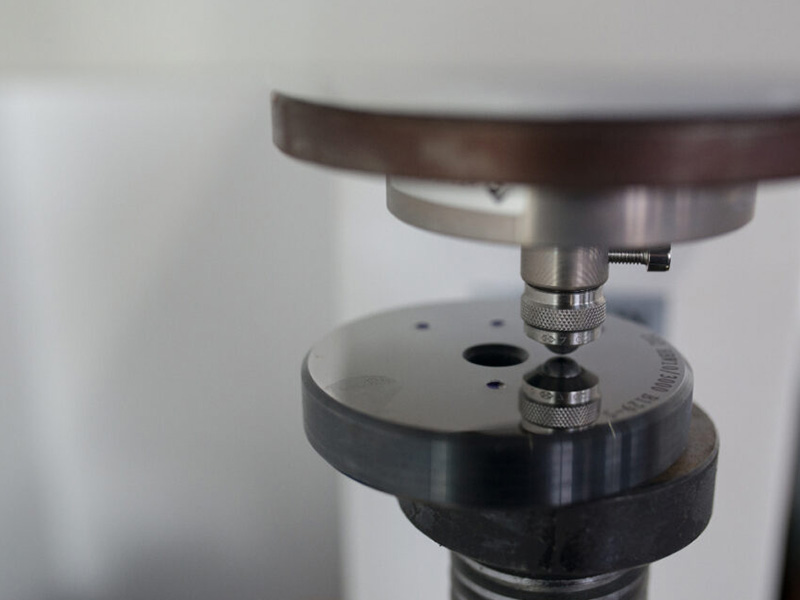

Hardness Test

Hardness – The quality or condition of being hard, A hardness test is typically performed by pressing a specifically dimensioned and loaded object (indenter) into the surface of the material you are testing. It is defined as the resistance to indentation, and it is determined by measuring the permanent depth of the indentation.

More simply put, when using a fixed force (load)* and a given indenter, the smaller the indentation, the harder the material. Indentation hardness value is obtained by measuring the depth or the area of the indentation using different test methods.

At COSMOS, The Rockwell Hardness Testing used to determine hardness, is defined in ASTM E18. The Rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods.

Corrosion, microstructure, and other Destructive tests are outsourced from certified laboratories in our network. This way, you are always assured of reliable measurement results.

Non-destructive analysis (NDT)

Each first article sample is tested for NDT, which helps to freeze product cycle, quality & hassle-free series production, NDT does not damage the cast piece to be analyzed, nor does it change it permanently. So it is a valuable technique that can save time and money in a product evaluation.

| Techniques | Defects on the Surface | Defects under the Surface |

| Visual inspection | Yes | No |

| Dye Penetrant analysis | Yes | No |

| Magnetic analysis | Yes | Yes |

| Radiographic analysis | Yes | Yes |

| Ultrasound analysis | Yes | Yes |

Visual Inspection

The oldest technique, and at the same time the most underestimated one, is visual inspection. the product and the material that must be analyzed are checked carefully for possible casting errors. With this technique, we can only provide an assessment of the piece’s surface.

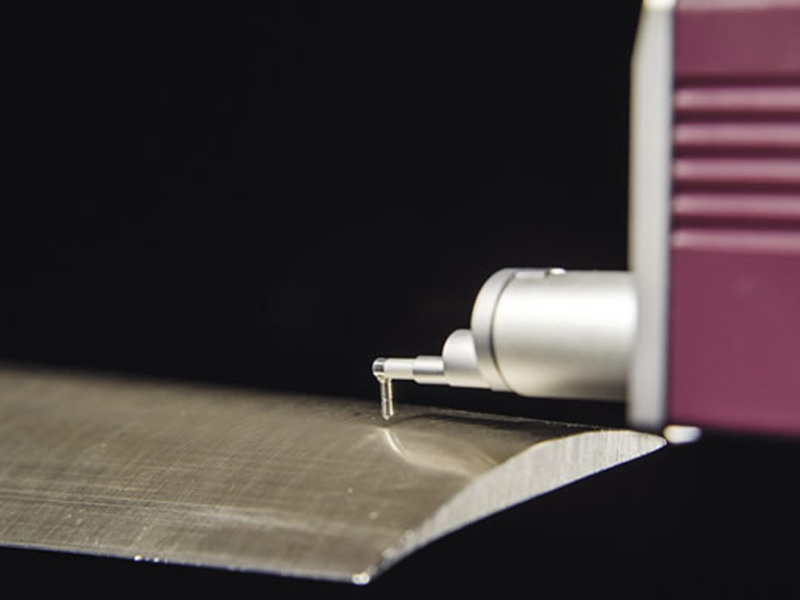

Dye Penetrant analysis

Dye Penetrant Inspection (DPI), also called Liquid Penetrant Inspection (LPI) or Penetrant Testing (PT), Liquid penetrant inspection is used to detect any surface-connected discontinuities such as cracks from fatigue, quenching, and grinding, as well as fractures, porosity, incomplete fusion, and flaws in joints

Magnetic analysis

This testing method is called MT (Magnetic Testing) or MPT (Magnetic Particle Testing), and suitable for the surface / subsurface (up to a maximum depth of 6 mm) flaw inspection of ferromagnetic materials.

It isn’t usable on stainless steel, 17-4PH, Duplex, Inconel, SiMo, Invar or Ni-Resist metals

Radiographic Analysis

Radiographic Testing (RT or X-ray or Gamma ray) is a non-destructive testing (NDT) method that examines the volume of a specimen. Radiography (X-ray) uses X-rays and gamma-rays to produce a radiograph of a specimen, showing any changes in thickness, defects (internal and external), and assembly details to ensure optimum quality in your operation.

Radiographic testing is outsourced to approved & certified test agencies.

Ultrasonic Testing

Ultrasonic nondestructive testing, also known as ultrasonic NDT or simply UT, is a method of characterizing the thickness or internal structure of a test piece through the use of high-frequency sound waves. The frequencies, or pitch, used for ultrasonic testing are many times higher than the limit of human hearing, most commonly in the range from 500 KHz to 20 MHz.

Radiographic testing is outsourced to approved & certified test agencies.